PREPARATIVE CHROMATOGRAPHY

SYSTEMS

DAC Columns For Liquid Chromatography (High Pressure)

Chromatography stands as one of the most versatile technologies for purification and separation, applied based on qualitative or quantitative objectives. While analytical chromatography serves qualitative analysis, preparative chromatography provides quantitative separation and purification of target molecules.

DAC COLUMNS

Sanitech delivers state-of-the-art preparative chromatography systems tailored to client separation and process requirements while meeting all international regulatory standards. Every system undergoes complete qualification and thorough testing during both Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT), with all systems suitable for cGMP applications. Our equipment complies with ASME construction codes and EC guidelines (DESP guidance).

Analytical HPLC | Preparative HPLC |

|---|---|

No recovery of individual components of substance | Individual components of substance can be recovered |

Use for qualification/indentification of compounds | Use for isolation and purification of compounds.

|

The quality of samples injected is small | The quality of samples injection volumes are large

|

Sample goes from detector to waste | Sample goes from detection to a fraction collector

|

Our Preparative HPLC DAC systems are capable of handling various separation and purification of complex molecules such as

- Peptide separation and purification

- Chiral compound/stereo isomer separation

- Highly potent API separation/purification

- Insulin

- Hormones

- Lipids

- Natural extract isolation

Dynamic Axial Compression (DAC)

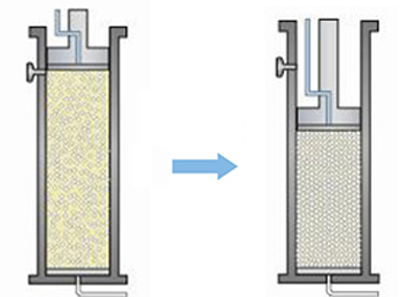

Dynamic Axial Compression (DAC) columns are specialized columns used in high pressure liquid chromatography. These columns enable effective chromatographic media packing, resulting in high-resolution separations and reduced analysis times.

- Enables the packing material to be compressed axially during the packing process.

- Adjustable column bed length as per client requirements

- Thermostat jacket for temperature control

- Optimum column performance with easy scale-up of your processes

- High-Pressure columns acclaimed for their durability

- Automated for fast and easy operation of columns

PUMPING

SYSTEM

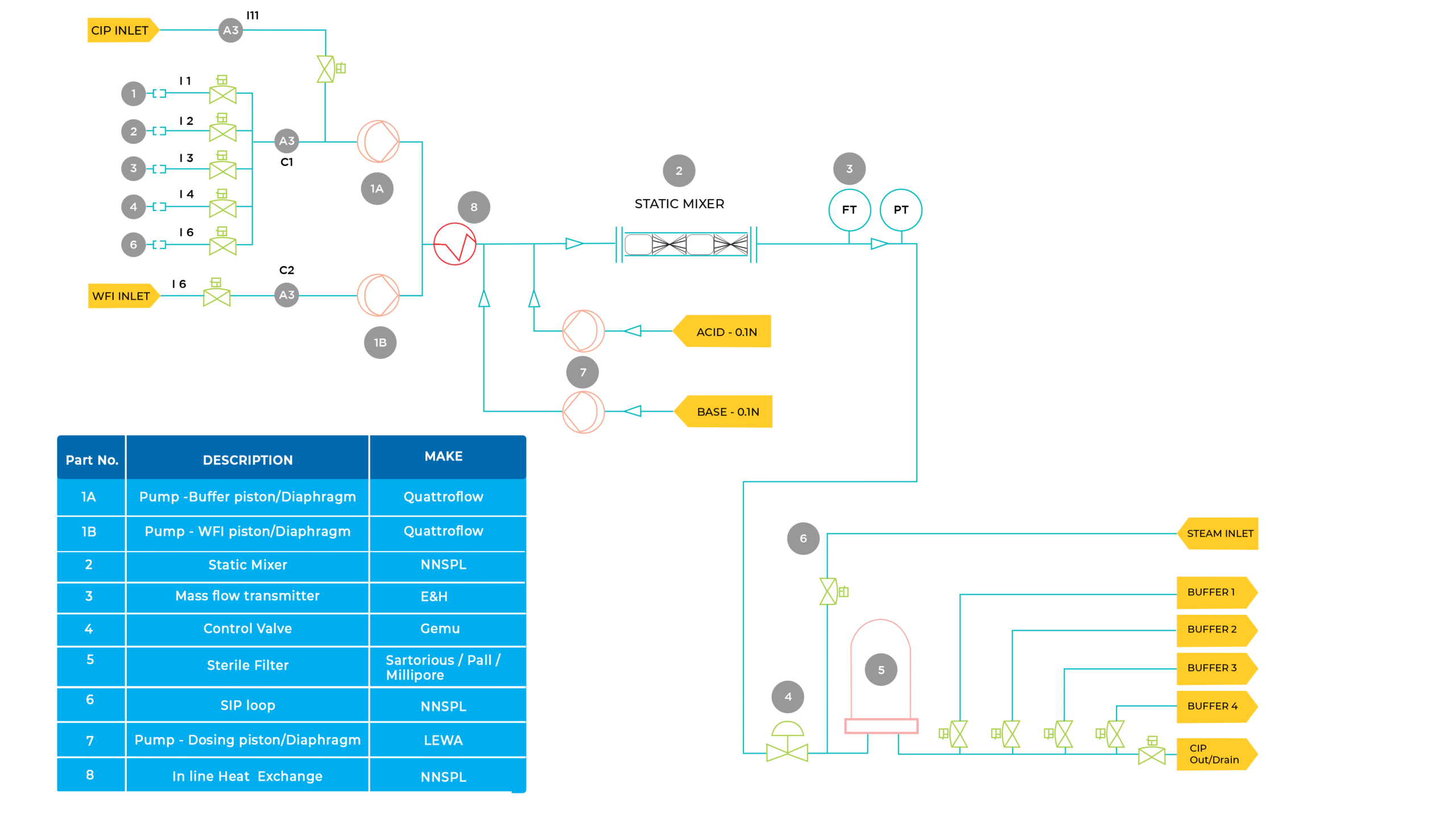

Columns and appropriate pumping systems are crucial components in process development. Beyond DAC columns, Sanitech provides fully automated pumping skids containing all necessary components for proper DAC column operation, including pumps, valves, sensors, and control systems.

Features of our Pumping Skid

- Engineered with a robust and efficient design

- Isocratic and gradient flow possibilities

- Ensures 24/7 continuous operation, while complying with PAT (Process Analytical Technology) guidelines of the FDA

- UV/RI wavelength detection system for automatic collection control

- Benefits of getting high productivity and yield resulting from a high accuracy and stability of operating parameters, such as flow rate, eluent composition, temperature, etc.

- Excellent process reproducibility and scalability from lab to industrial plants

- Easy and fast maintenance, and validated and user-friendly software for easy start-up

- User-friendly touchscreen interface to monitor for controlling the chromatography process

- Easy integration of existing chromatography systems into any laboratory or production facility

- Training with on-site qualifications

- Flameproof, ATEX, GAMP V, 21CFR Part 11, for Zone 1 and 2

- Material certificates for 3.1 & 2.1 CODAP/ASME Compliance

SLURRY PACKING

UNIT

Effective slurry charging is essential for proper DAC packing to achieve efficient column packing. Therefore, slurry charging and packing equipment becomes crucial in preparative chromatography. Our closed mixing unit readily integrates with large-diameter DAC preparative columns.

The column packing can be performed in very few simple steps:

- Filling vessel with buffer as recommended by manufacture/R&D team followed by media to be used

- Gentle mixing with a pneumatic agitator provided in the unit

- Removing fine particles after the solution is at rest if required

- Make a uniform slurry using a buffer and charge the empty column using a pneumatic slurry transfer pump

Sanitech’s customer-focused slurry charging unit design enables easy installation in hazardous areas without electrical power requirements. Column packing requires only a few simple steps for completion.

Features of the unit:

- Fully non-electrical pneumatic unit with agitator and slurry transfer pump

- SS316/SS316L mixing vessel

A GLIMPSE OF THIS PRODUCT

Watch This Product In 360°

Rotate the product using mouse to experience product in 360°