Membrane Systems

Reverse Osmosis System

Reverse osmosis (RO) serves as a highly effective membrane filtration technology used across diverse industries for water recovery and dissolved material concentration. This proven method employs semi-permeable membranes with extremely fine pores to separate contaminants and solutes from solvents.

By applying pressure to force water molecules through the membrane while leaving behind ions, larger particles, and dissolved solids, reverse osmosis provides a reliable and energy-efficient solution for producing high-quality water and concentrating valuable substances across industrial and residential applications.

Sanitech Engineers develops state-of-the-art reverse osmosis membrane solutions with systems meeting all international regulatory standards.

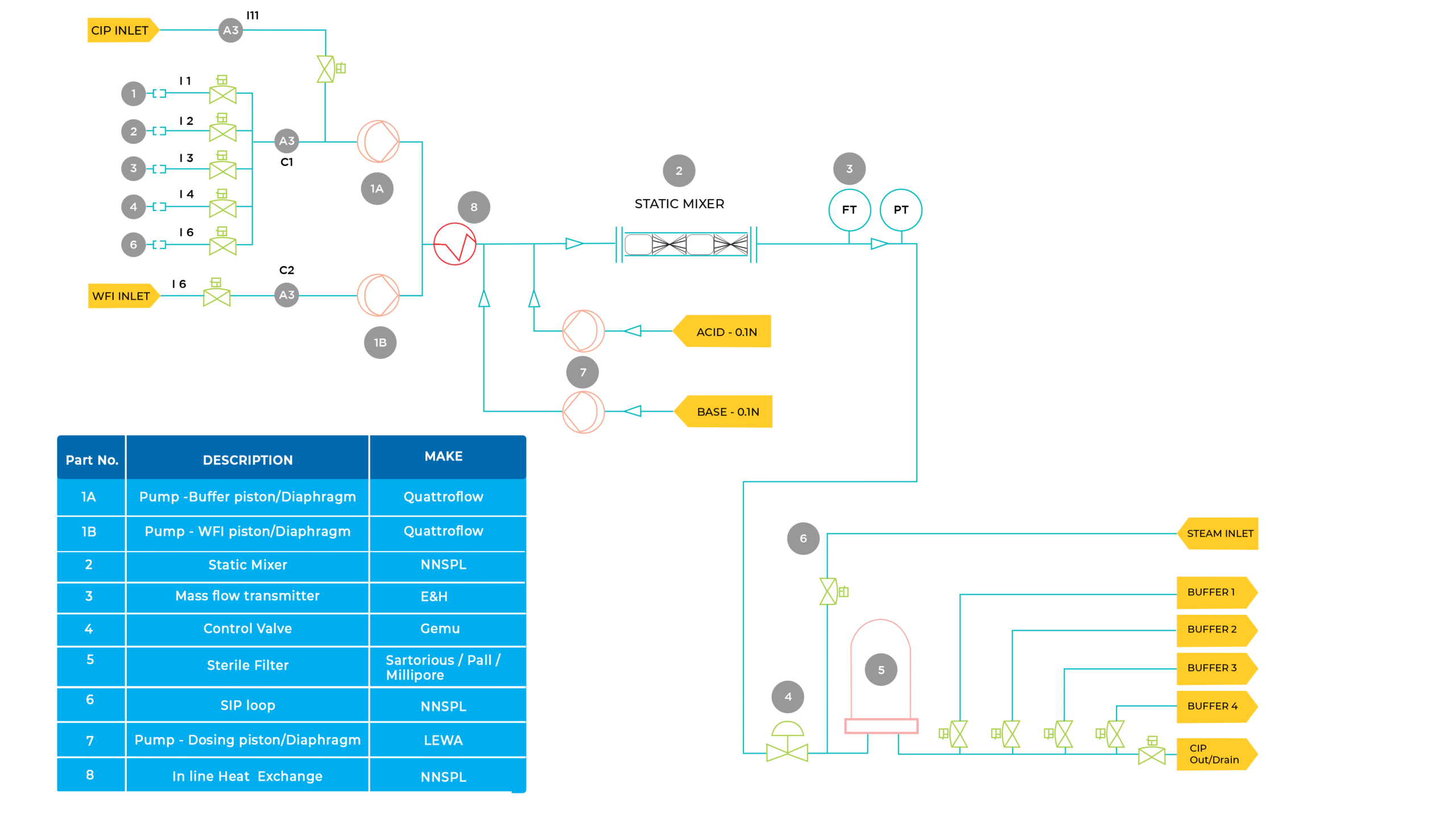

System Components & Features:

- High-Performance Membranes: Specialized semi-permeable membranes featuring thin-film composite materials like polyamide with ultra-fine pores that allow water molecules to pass while rejecting contaminants and dissolved solids

- Precision Pressure Systems: Integrated pressure pumps generate the necessary hydraulic pressure to overcome osmotic pressure and drive efficient separation

- Comprehensive Pre-filtration: Multi-stage pre-filtration removes sediment, larger particles, chlorine, and other contaminants that could compromise membrane integrity, with our microfiltration, ultrafiltration, and nanofiltration systems providing ideal upstream treatment

- Engineered Pressure Vessels: Robust housing ensures uniform hydraulic pressure distribution across membrane surfaces for consistent, reliable filtration

- Dual Stream Output: Process generates two distinct streams – purified permeate water and concentrated reject stream containing filtered impurities, both carefully separated and collected

- Advanced Flow Control: Precise flow control mechanisms maintain steady feed water and permeate flow rates for reliable system performance

- Intelligent Automation: Sophisticated control systems monitor and adjust pressure, flow rates, and cleaning cycles for optimal operation with minimal operator intervention

- Integrated CIP Systems: Dedicated clean-in-place systems for routine membrane maintenance and cleaning, preventing fouling and ensuring long-term performance

- Comprehensive Monitoring: Advanced sensors and alarm systems provide real-time detection of potential issues and deviations from optimal operating conditions

Key Applications:

- Desalination: Essential technology for converting seawater and brackish water into potable water

- Industrial Water Production: Manufacturing ultra-pure water for critical industrial processes

- Food & Beverage Processing: Juice concentration, beverage clarification, and process water purification

- Pharmaceutical Manufacturing: Production of purified water for pharmaceutical processes and Water for Injection (WFI) applications

- Water Recovery: Efficient water recovery from various industrial process streams

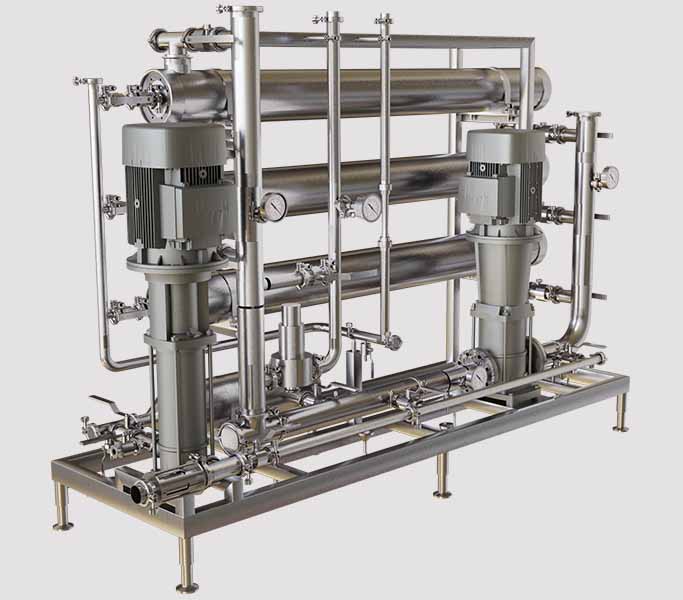

A GLIMPSE OF THIS PRODUCT

Watch This Product In 360°

Rotate the product using mouse to experience product in 360°