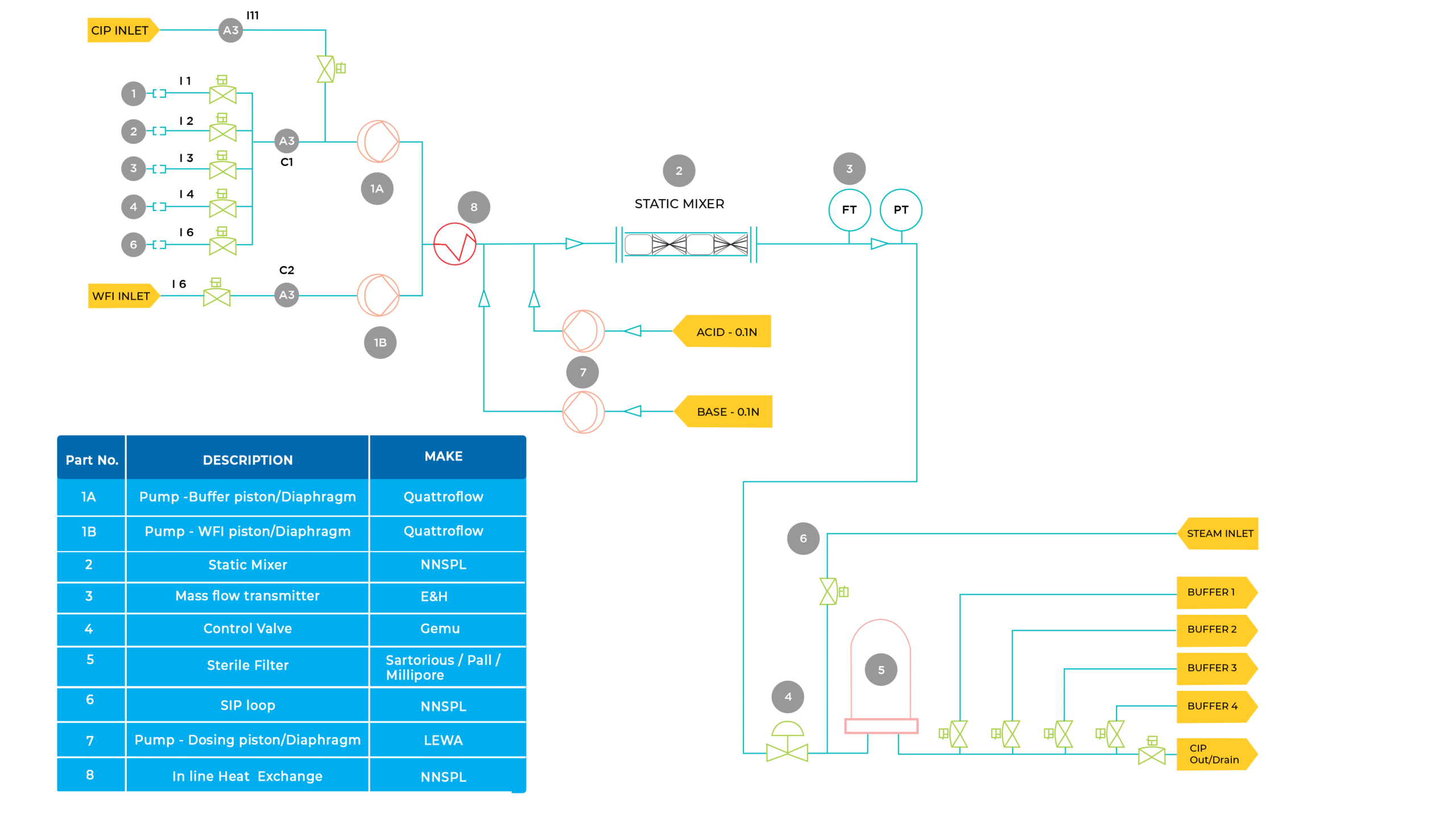

Membrane Systems

Microfiltration System

Microfiltration (MF) represents one of the most effective methods for removing impurities and particles from fluid streams. This process employs specialized porous membranes with precisely controlled pore sizes, allowing smaller particles to pass through while retaining larger contaminants.

The widespread adoption of microfiltration across industries including food and beverage processing, pharmaceuticals, nutraceuticals, dairy, and biotechnology stems from its reliability and cost-effectiveness in clarifying fluids and removing suspended solids.

Sanitech Engineers leads the field in microfiltration membrane solutions, with systems designed to meet the most stringent international regulatory standards.

Features

Microfiltration Membrane

Our system utilizes a specialized membrane with pore sizes typically ranging from 0.1 to 0.6 microns, serving as a physical barrier for particles larger than the pores.

Cross-Flow Microfiltration Mode

Our system operates with cross-flow or tangential flow filtration, preventing membrane clogging and enhancing filtration efficiency.

Pressure Control (TMP)

The system incorporates pressure control mechanisms, optimizing filtration by maintaining specific pressure differentials across the membrane.

Modular Design

Our modular design ensures flexibility in system configuration, allowing easy scaling based on application requirements. Modules can be added or removed to adjust the system's capacity and accommodate different process needs.

- Precision Membrane Technology: Our systems utilize specialized membranes with pore sizes ranging from 0.1 to 0.6 microns, creating an effective physical barrier for larger particles

- Cross-Flow Operation: Enhanced filtration efficiency through cross-flow or tangential flow filtration, significantly reducing membrane clogging

- Advanced Pressure Control: Optimized transmembrane pressure (TMP) management ensures maximum filtration performance

- Modular Flexibility: Scalable design allows easy capacity adjustments by adding or removing modules to meet varying process requirements

- Automated Operations: Integrated controls, sensors, and alarms ensure consistent, efficient filtration performance

- Comprehensive Maintenance: Multiple cleaning options including chemical cleaning, backwashing, and membrane replacement keep systems operating at peak efficiency

- Application-Specific Customization: Tailored features for specific industries, from pharmaceutical validation requirements to food industry sanitary standards

- Material Versatility: Choice of stainless steel grades (SS316, SS316L, SS304) to match application requirements

- Universal Compatibility: Support for membranes from leading manufacturers using various materials including ceramic and polymeric options like PVDF

- Intelligent Monitoring: Real-time tracking of critical parameters including temperature, pressure, flow rate, pH, and conductivity

- Space-Efficient Design: Compact systems suitable for both laboratory and large-scale industrial applications

Applications

- Clarification of beverages including juices, wines, beers, and dairy products for enhanced stability and extended shelf life

- Pharmaceutical purification, concentration, and particle removal

- Biotechnology applications including sterile filtration, protein harvesting, cell separation, and fermentation broth clarification

- Dairy processing for milk standardization, bacterial removal, and improved product safety

- Food processing for clarification, separation, and concentration of juices, sauces, and dressings

- Electronics manufacturing for process fluid purification

- Nanoparticle concentration and purification in advanced material synthesis

A GLIMPSE OF THIS PRODUCT

Watch This Product In 360°

Rotate the product using mouse to experience product in 360°